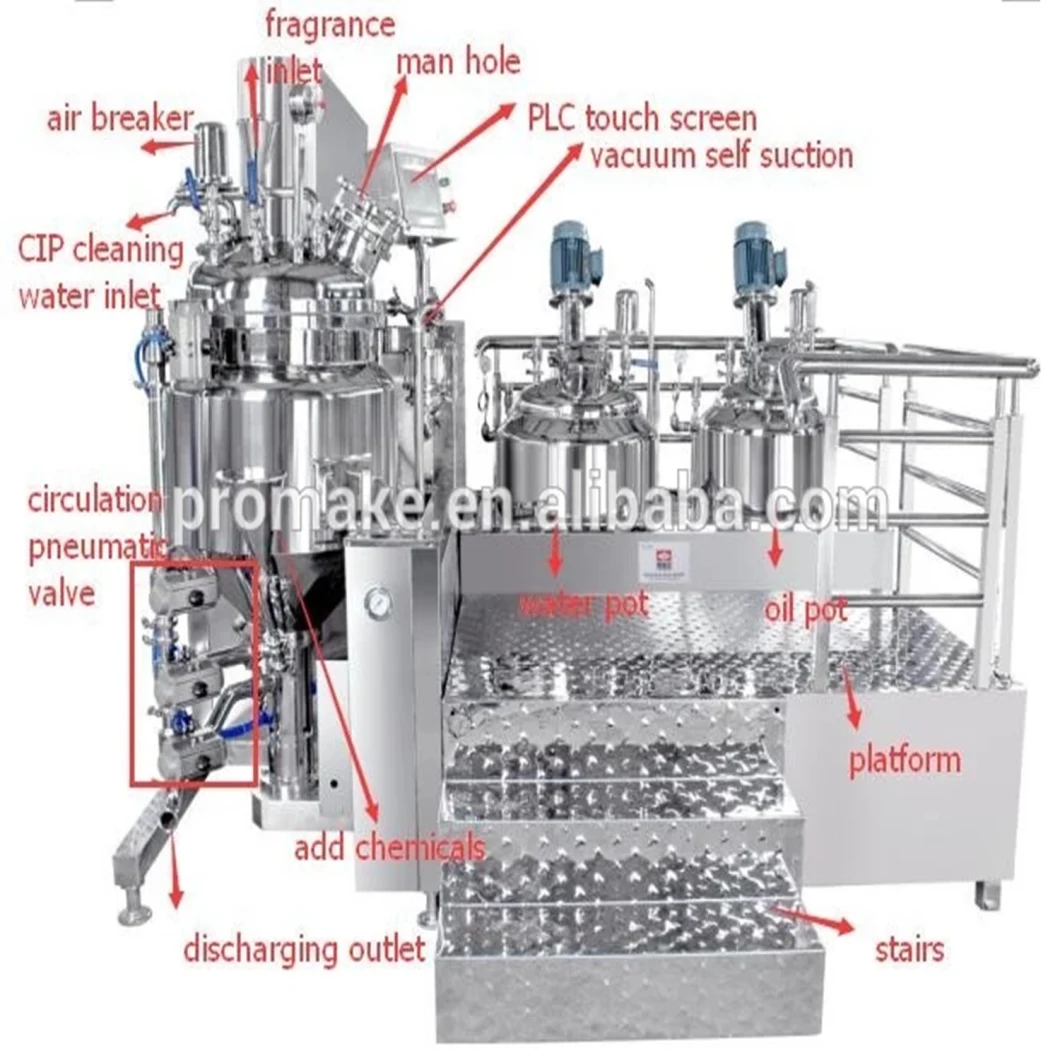

Germany technology 200L mixing emulsifying homgenizer

Feature:

1) Can handle processing small doses of high viscosity product to replace the traditional process

2) Equipment adopts the piston valve, easy to deal with blind area, ensure material in everything in a part

3) Equipment level 3 emulsion shear force produced by homogeneous head makes the solute transfer speed increases, so that a single molecules and macro molecular decomposition

speed, at the same time have the best rotor, electrical generators, can according to the size of the dispersed particles

4) All equipment within the automatic weighing system, feeding and discharging all achieve automatic control, more safety, health fully meet GMP standard.

5) Adopt PLC control , all the operation can be controlled on PLC touch screen

Products:

Parameters:

1)Main pot:design 200L ,working capacity :150L

Scraper blade mixing motor :1.1KW , reverse direction:0.75KW, mixing speed:0-65r/m

Bottom homogenizer :5.5KW, rotary speed:0-4000r/m

main pot | Configuration and parameters | Remark |

Design volume: | Full volume:200L;working volume:150L; | Load factor: 0.8 |

Heating method: | Jacket by steam heating ,pneumatic automatically control | Working pressure:2kg |

Basic structure | Three layers,mixing with scraper,separately control bidirectional mixing |

|

Pot material | Material contacts with products ,inside layer :SUS 316L , thickness:4mm |

|

| Middle layer:SUS304, thickness:4mm |

|

| Outside layer:SUS 304 , thickness:4mm |

water pot | Configuration and parameters | Remark |

Design volume | Full volume:150L , working volume :120L |

|

Heating way | Jacket by steam heating ,pneumatic automatically control | Working pressure:2kg |

Structure | 3 layers ,sealing manhole type ,top with high speed disperser |

|

Pot material | Material contacts with products ,inside layer :SUS 316L , thickness:4mm |

|

| Middle layer:SUS304, thickness:3mm | Jacket thickness:50mm |

| Outside layer:SUS 304 , thickness:3mm | Insulation medium: aluminum silicate |

Disperser | Top installed high speed disperser , motor power:1.5KW, speed:1440r/m; | ABBmotor |

| Oil pot | Configuration and parameters | Remark |

Design volume | Full volume:80L;working volume:60L; |

|

Heating type | Jacket steam heating |

|

Basic structure | Three layers , sealed manhole , top with high speed disperser |

|

Pot material | Material contacts with products ,inside layer :SUS 316L , thickness:4mm |

|

| Middle layer:SUS304, thickness:3mm | Jacket thickness:50mm |

| Outside layer:SUS 304 , thickness:3mm | Insulation medium: aluminum silicate |

Disperser | Top installed high speed disperser , motor power:1.5KW, speed:1440r/m; | ABB()motor /Siemens |

Circulation system :

This part abosorbed Germany IKA technology .The mixer and homogenizer can ciculate material at

the different level .Thus can make the material at small volume sample production to batch production . Circulation

ensure the finished cream products with soft and evenly affect .

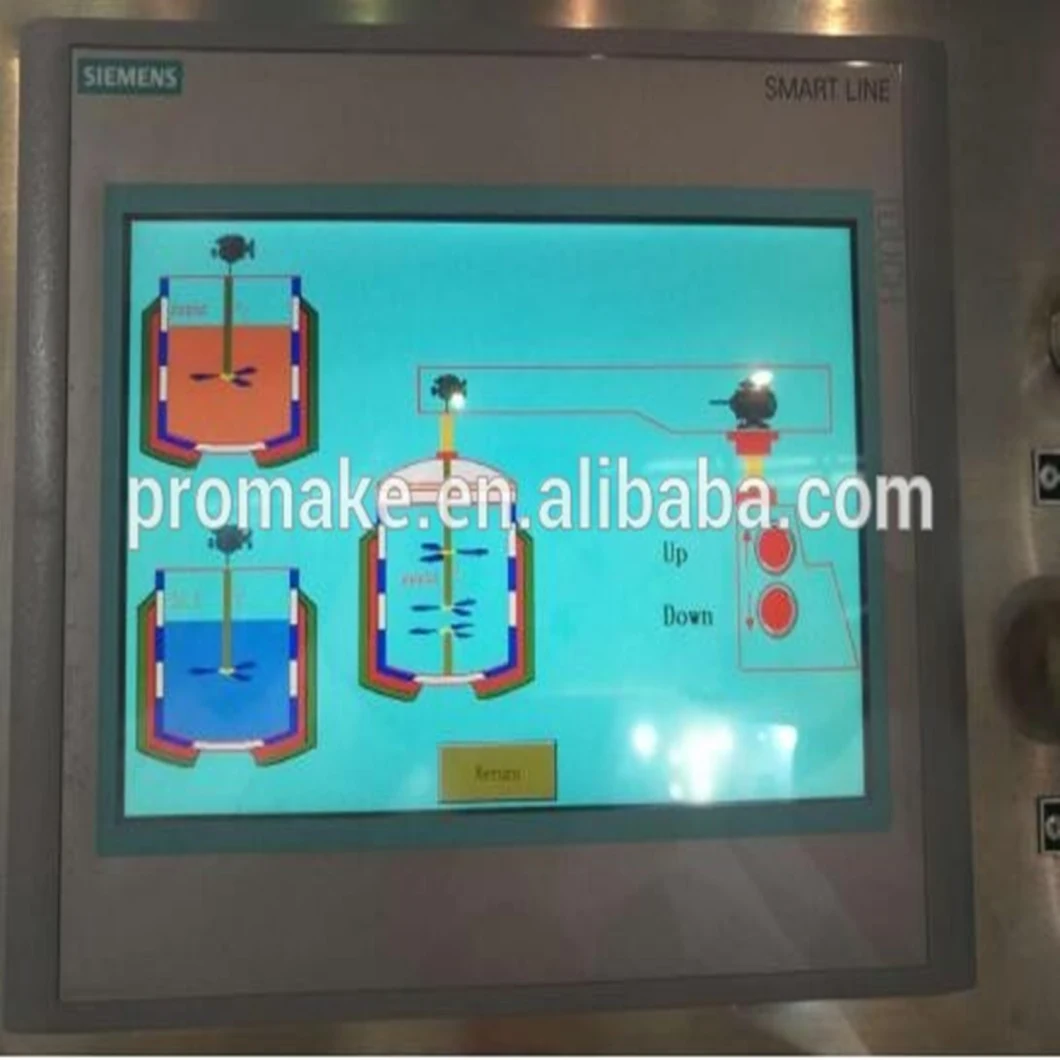

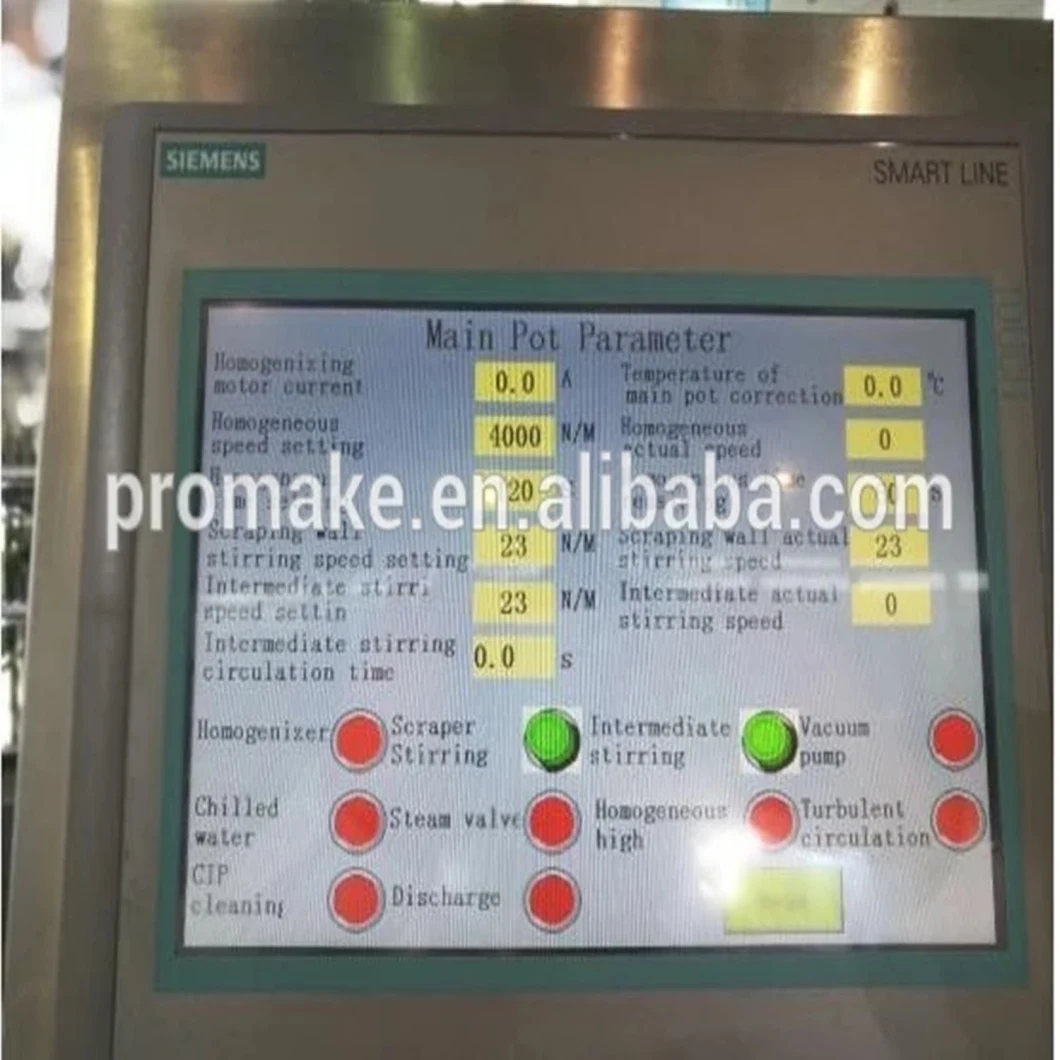

Siemens PLC touch screen control :

can control the heating start/off , heating temperature ,

mixing and homogenizing start/off , time , speed

vacuum system,lifing system , circulation system , etc .