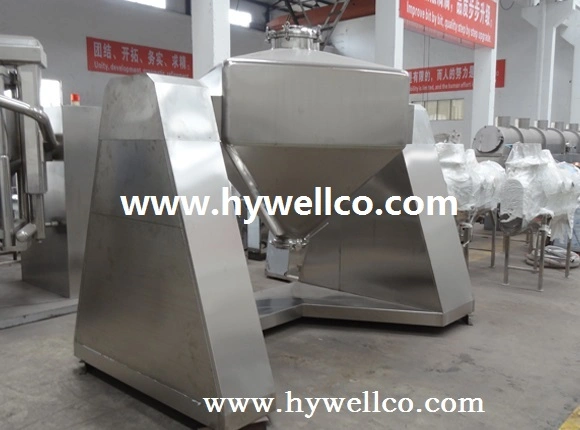

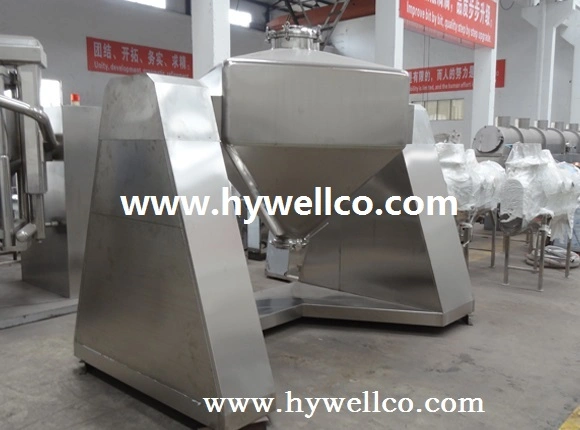

Hywell machinery design and manufacture the HF Square Cone mixing machine that volume from 5 to 3000L (load 2.5-1500kg per batch), as client requirement , we can design the the mixing machine with weight system so that replace the manual to weight different kinds powder. about the feeding system, we can design screw feeder or vacuum feeder .if you need the mixing machine, welcome to contact hywell machinery company.

Principle

Materials are charged into a closed square-cone mixing barrel, the symmetrical axes of hopper and the axes of rotating shaft form an included angle, materials with different constituents are strenuously rolling over in the closed hopper and producing high shear to achieve the best effect of mixing.

Features

1.The whole machine features novel design, compact structure, and good appearance, the evenness of mixing reaches 99% , and the volume charge factor reaches 0.8.

2. Smooth running, reliable performance, easy operation.

3. Highly polished inner and outer surfaces of the barrel, no dead comer, easy to discharge materials, easy to clear, no cross contamination. Confining to the requirement of GMP.

4. Control system has more choices, such as push button ,HMI+PLC and so on

5. The feeding system for this mixer can be by manual or pneumatic conveyor or vacuum feeder or screw feeder and so on

6. Machine materials : AISISUS304 , AISISUS316L, and other material .

Application

HF Series Square Cone Mixer is extensively used in the pharmaceutical, chemical, metallurgical, food, light and feed industries. This machine can mixer powder or granules very evenly so that the mixed materials can reach the best effect

Attention to order

1. When inquiry the HF Series Square Cone Mixer, Client need to supply the materials state: powder or granules.

2. When inquiry the HF Series Square Cone Mixer, Client need to supply the density of materials.

3. When inquiry the HF Series Square Cone Mixer, Client need to supply the capacity per batch or capacity per hour.

5. When inquiry the HF Series Square Cone Mixer, Client need to decide which kinds feeder that needed to load materials into mixer.

6. When inquiry the HF Series Square Cone Mixer, Client need to decide which kinds steel for machine-304 stainless steel or 316L stainless steel.

7. Other special requirements.

About Us:

From dryer machine, mixing machine to granulation machine, from unit machine to production line, we have them all. Hywell Machinery is a professional manufacturer of industrial dryer, powder mixer and granulation machine. Our flagship products include the drying oven, fluid bed dryer, belt dryer, vacuum dryer machine, rotary flash dryer, chamber drying machine, single dimensional powder blender, three dimensional mixer, two dimensional mixer and high shear granulation machine, continuous granulator and so on. These high-performance machines have extensive applications within industries such as food, medicine and chemical. Sustained development and a strong emphasis on research and technology have bolstered our quality standards. we seek to achieve the highest level of customer satisfaction through professionally developed drying, mixing and granulation solutions. Hywell Machinery constant faith is providing perfect products to customer, excellenting service to client !

Quality control

In order to ensure quality of product, we focus on user 's requirements and control improvement and enhancement quality of products .The quality assurance mainly focus on the processes of ensuring production readiness inspection, control of raw materials and components, process control, critical parts, important parts of quality control, assembly quality control, process control testing, measurement equipment control. Pay close attention to the implementation of the quality assurance work, strictly to three inspection system of self-checking, mutual inspection, special inspection. The key point of Quality assurance is focuses on critical parts, important parts of quality control, the quality standards required by ISO9000 quality control procurement documents in order to clarify its status and acceptance of quality standards for company's re-inspections ; For critical parts and important that the key processes of identification and corresponding technical documentation, control by "the implementation of key quality control process", and complete, accurate and complete original records. Difficulties in quality assurance is a special process control, quality assurance is mainly painting, has developed a special process (painting) process documents, take the appropriate technical measures, to quality assurance.

In the production process, we pay close attention to quality control of each process. Every component, every process was strictly controlled. Enhanced the quality inspection process, the establishment of the necessary quality control point, the process by a full-time staff and quality inspector for inspection and supervision. Improved testing procedures and operating instruction.

OUR SERVICES

Pre-sale service

We invite customers to visit our company and communicate on technical requirements face to face. we also can do test in our lab for free. and then we will use the testing parameter to design final machine to reach client requirement.

Sale service

Responsible for debugging the equipment according to customers' requirements of various technical data. Our engineers will train our customers about equipment features and operation key points to make sure the equipment running in the best condition.

After-sale service

We provide installation, debugging, maintenance, training and other services (Optional); Provide relevant technical data, equipment, software and related GMP certification materials.

Quality promise

Our company promises strictly operate the ISO9001 quality system certification standards and pharmaceutical equipment GMP audit requirements,promise we provide new equipment. Advanced technology,good quality. Equipment operation safe reliable, affordable, easy to maintain.

Equipment warranty period is one year, all the parts for the equipment choose well-known brand.During the warranty when equipment have problem in quality like equipment failure and damage, our company offer free maintenance or replacement.

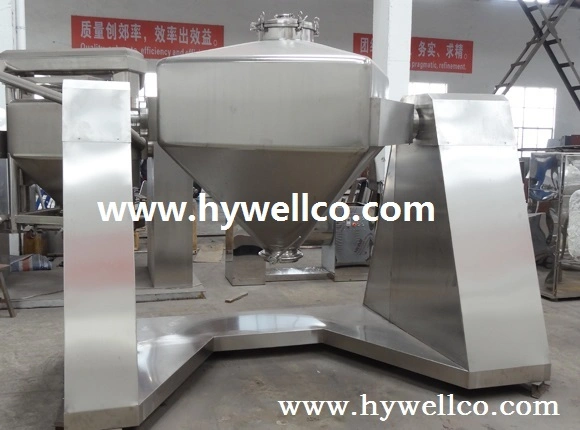

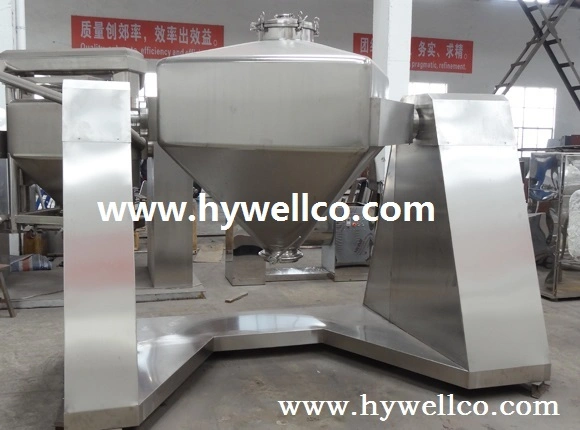

Principle

Materials are charged into a closed square-cone mixing barrel, the symmetrical axes of hopper and the axes of rotating shaft form an included angle, materials with different constituents are strenuously rolling over in the closed hopper and producing high shear to achieve the best effect of mixing.

Features

1.The whole machine features novel design, compact structure, and good appearance, the evenness of mixing reaches 99% , and the volume charge factor reaches 0.8.

2. Smooth running, reliable performance, easy operation.

3. Highly polished inner and outer surfaces of the barrel, no dead comer, easy to discharge materials, easy to clear, no cross contamination. Confining to the requirement of GMP.

4. Control system has more choices, such as push button ,HMI+PLC and so on

5. The feeding system for this mixer can be by manual or pneumatic conveyor or vacuum feeder or screw feeder and so on

6. Machine materials : AISISUS304 , AISISUS316L, and other material .

Application

HF Series Square Cone Mixer is extensively used in the pharmaceutical, chemical, metallurgical, food, light and feed industries. This machine can mixer powder or granules very evenly so that the mixed materials can reach the best effect

Attention to order

1. When inquiry the HF Series Square Cone Mixer, Client need to supply the materials state: powder or granules.

2. When inquiry the HF Series Square Cone Mixer, Client need to supply the density of materials.

3. When inquiry the HF Series Square Cone Mixer, Client need to supply the capacity per batch or capacity per hour.

5. When inquiry the HF Series Square Cone Mixer, Client need to decide which kinds feeder that needed to load materials into mixer.

6. When inquiry the HF Series Square Cone Mixer, Client need to decide which kinds steel for machine-304 stainless steel or 316L stainless steel.

7. Other special requirements.

| Model | HF-5 | HF-20 | HF-50 | HF-100 | HF-300 | HF-500 | HF-1000A | HF-1500A | HF-2000A | HF-3000A |

| Volume of barrel(L) | 5 | 20 | 50 | 100 | 300 | 500 | 1000 | 1500 | 2000 | 3000 |

| Max. load volume(L) | 5 | 20 | 50 | 80 | 240 | 400 | 800 | 1200 | 1600 | 2400 |

| Max. load weight(kg) | 2.5 | 9 | 25 | 50 | 150 | 250 | 500 | 750 | 1000 | 1500 |

| Main shaft speed(rpm) | 16 | 16 | 16 | 15 | 14 | 13 | 12 | 10 | 10 | 8 |

| Motor power (kW) | 1.1 | 1.1 | 1.1 | 1.5 | 1.5 | 2.2 | 4 | 5.5 | 7.5 | 11 |

| Weight (kg) | 300 | 300 | 350 | 400 | 600 | 750 | 1200 | 1650 | 2000 | 3000 |

| Overall dimension (L×W×H)(m) | 1.2x0.5 x0.9 | 1.2x0.5 x0.9 | 1.25x0.6 x1 | 1.35X0.6 X1.1 | 1.85×1.3 ×1.9 | 2.2×1.5 ×2.22 | 2.8×2.0 x2.8 | 2.98×2.33 ×3.07 | 3.3×2.55 ×3.3 | 3.8×3.0 ×3.8 |

About Us:

From dryer machine, mixing machine to granulation machine, from unit machine to production line, we have them all. Hywell Machinery is a professional manufacturer of industrial dryer, powder mixer and granulation machine. Our flagship products include the drying oven, fluid bed dryer, belt dryer, vacuum dryer machine, rotary flash dryer, chamber drying machine, single dimensional powder blender, three dimensional mixer, two dimensional mixer and high shear granulation machine, continuous granulator and so on. These high-performance machines have extensive applications within industries such as food, medicine and chemical. Sustained development and a strong emphasis on research and technology have bolstered our quality standards. we seek to achieve the highest level of customer satisfaction through professionally developed drying, mixing and granulation solutions. Hywell Machinery constant faith is providing perfect products to customer, excellenting service to client !

Quality control

In order to ensure quality of product, we focus on user 's requirements and control improvement and enhancement quality of products .The quality assurance mainly focus on the processes of ensuring production readiness inspection, control of raw materials and components, process control, critical parts, important parts of quality control, assembly quality control, process control testing, measurement equipment control. Pay close attention to the implementation of the quality assurance work, strictly to three inspection system of self-checking, mutual inspection, special inspection. The key point of Quality assurance is focuses on critical parts, important parts of quality control, the quality standards required by ISO9000 quality control procurement documents in order to clarify its status and acceptance of quality standards for company's re-inspections ; For critical parts and important that the key processes of identification and corresponding technical documentation, control by "the implementation of key quality control process", and complete, accurate and complete original records. Difficulties in quality assurance is a special process control, quality assurance is mainly painting, has developed a special process (painting) process documents, take the appropriate technical measures, to quality assurance.

In the production process, we pay close attention to quality control of each process. Every component, every process was strictly controlled. Enhanced the quality inspection process, the establishment of the necessary quality control point, the process by a full-time staff and quality inspector for inspection and supervision. Improved testing procedures and operating instruction.

OUR SERVICES

Pre-sale service

We invite customers to visit our company and communicate on technical requirements face to face. we also can do test in our lab for free. and then we will use the testing parameter to design final machine to reach client requirement.

Sale service

Responsible for debugging the equipment according to customers' requirements of various technical data. Our engineers will train our customers about equipment features and operation key points to make sure the equipment running in the best condition.

After-sale service

We provide installation, debugging, maintenance, training and other services (Optional); Provide relevant technical data, equipment, software and related GMP certification materials.

Quality promise

Our company promises strictly operate the ISO9001 quality system certification standards and pharmaceutical equipment GMP audit requirements,promise we provide new equipment. Advanced technology,good quality. Equipment operation safe reliable, affordable, easy to maintain.

Equipment warranty period is one year, all the parts for the equipment choose well-known brand.During the warranty when equipment have problem in quality like equipment failure and damage, our company offer free maintenance or replacement.