Product Description

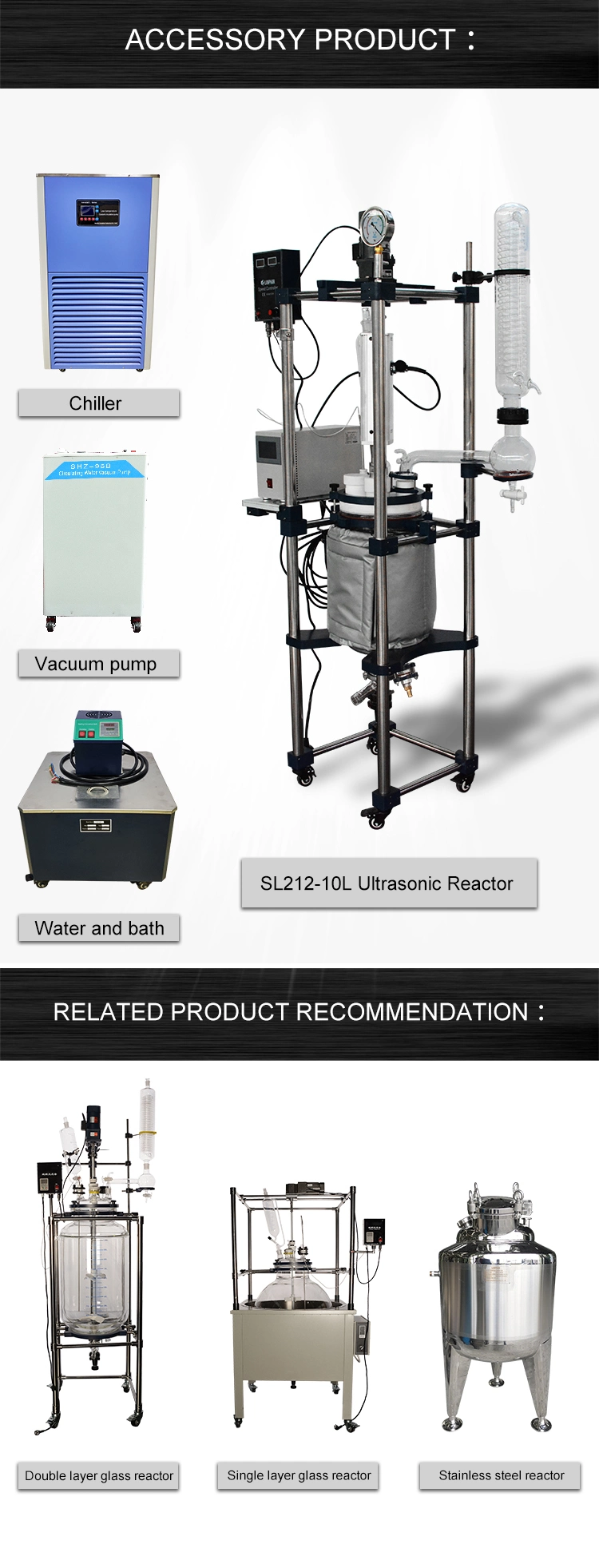

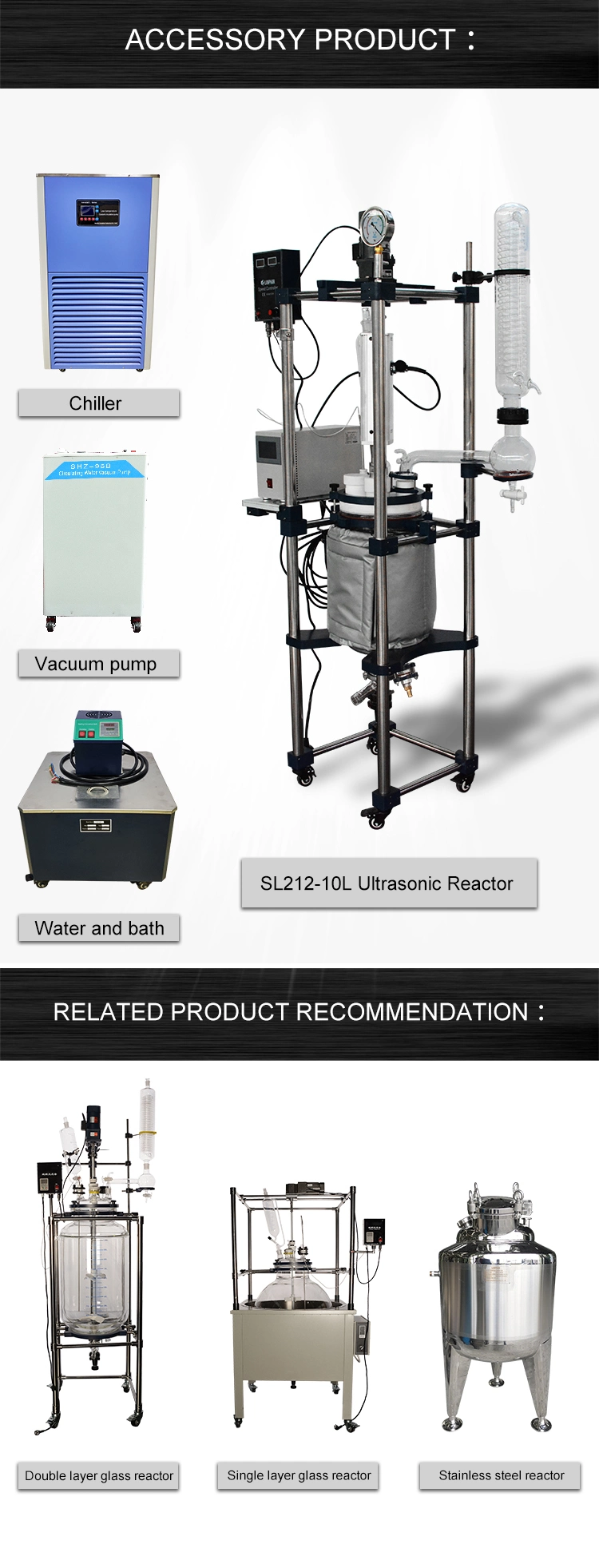

The SL212 series ultrasonic double layer glass reactor adopts double-layer glass design. The reaction solvent can be put in the internal layer to do the stirring reaction, and different cold and heat sources (refrigerating fluid, hot water or oil) can be connected to the interlayer to do the circulating heating or cooling reaction. And the ultrasonic device is equipped, which can save solvent, speed up the reaction process, enhance both the extraction rate and the dissolution rate. At a constant temperature, the stirring reaction can be done under normal or negative pressure, as well as the backflow and distillation of the reaction solution. It is an ideal pilot-plant and production equipment for modern fine chemical industry, biopharmaceutical and new material synthesis.

The SL212 series ultrasonic double layer glass reactor adopts double-layer glass design. The reaction solvent can be put in the internal layer to do the stirring reaction, and different cold and heat sources (refrigerating fluid, hot water or oil) can be connected to the interlayer to do the circulating heating or cooling reaction. And the ultrasonic device is equipped, which can save solvent, speed up the reaction process, enhance both the extraction rate and the dissolution rate. At a constant temperature, the stirring reaction can be done under normal or negative pressure, as well as the backflow and distillation of the reaction solution. It is an ideal pilot-plant and production equipment for modern fine chemical industry, biopharmaceutical and new material synthesis.

An ultrasonic double layer is an ideal equipment for lab-scale and pilot tests, biopharmaceutical, new drug research and development and new material synthesis. It is primarily used in small chemical industry, petroleum, metallurgy, coal, electronics, building materials, light industry and other fields, or the medium and small scale production.

Our Service

Our Service

The SL212 series ultrasonic double layer glass reactor adopts double-layer glass design. The reaction solvent can be put in the internal layer to do the stirring reaction, and different cold and heat sources (refrigerating fluid, hot water or oil) can be connected to the interlayer to do the circulating heating or cooling reaction. And the ultrasonic device is equipped, which can save solvent, speed up the reaction process, enhance both the extraction rate and the dissolution rate. At a constant temperature, the stirring reaction can be done under normal or negative pressure, as well as the backflow and distillation of the reaction solution. It is an ideal pilot-plant and production equipment for modern fine chemical industry, biopharmaceutical and new material synthesis.

The SL212 series ultrasonic double layer glass reactor adopts double-layer glass design. The reaction solvent can be put in the internal layer to do the stirring reaction, and different cold and heat sources (refrigerating fluid, hot water or oil) can be connected to the interlayer to do the circulating heating or cooling reaction. And the ultrasonic device is equipped, which can save solvent, speed up the reaction process, enhance both the extraction rate and the dissolution rate. At a constant temperature, the stirring reaction can be done under normal or negative pressure, as well as the backflow and distillation of the reaction solution. It is an ideal pilot-plant and production equipment for modern fine chemical industry, biopharmaceutical and new material synthesis.| Basic Parameters | Model | S212-10L |

| Glass Material | GG-17 | |

| Frame Material | Stainless steel | |

| Pipe Fitting Material | SS 304 | |

| Moving Mode | Universal casters with braking | |

| Volume of Reaction Flask | 10L | |

| Interlayer Volume | 6L | |

| Flange Type Oil Inlet and Outlet | Low in and high out | |

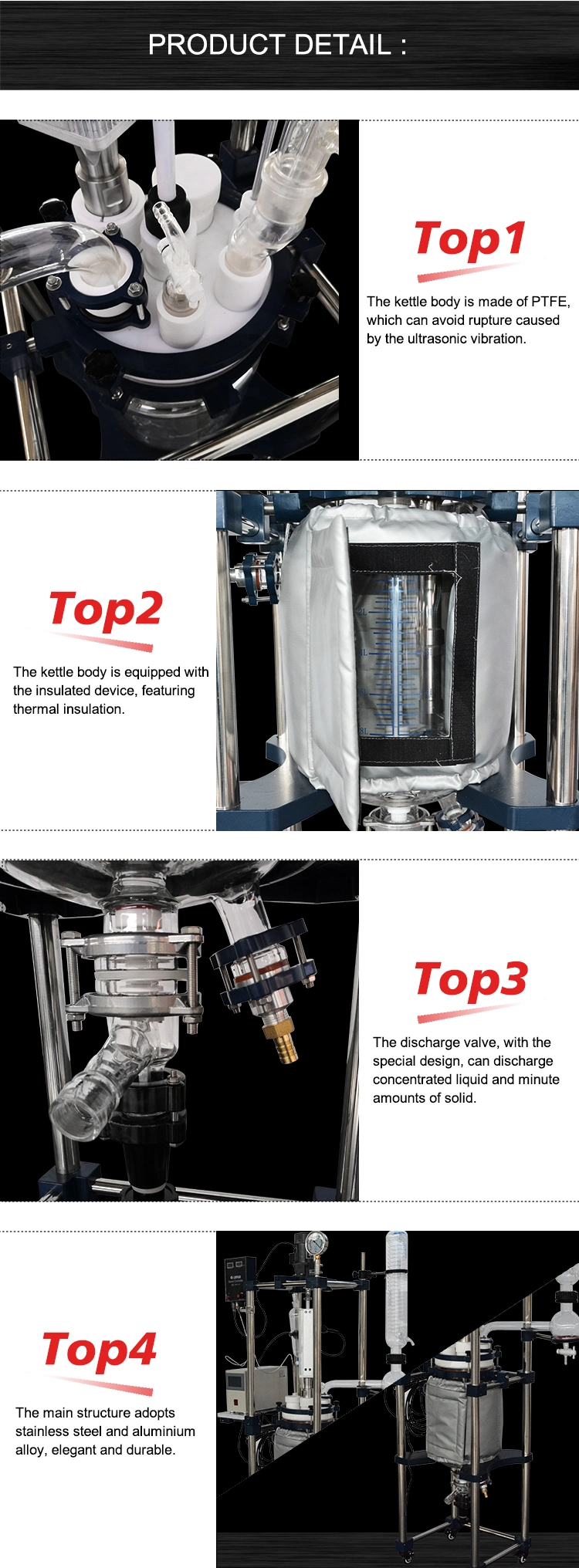

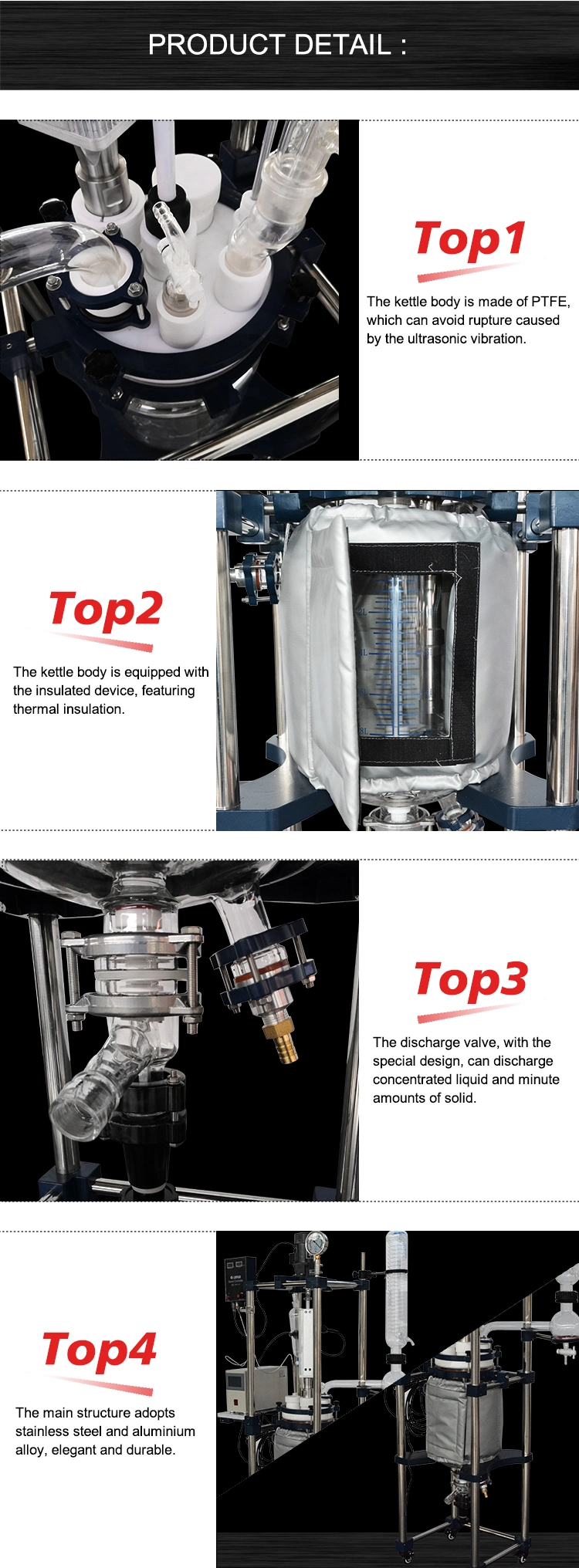

| Flask Necks of Kettle Cover | PTFE seven ports | |

| Height of Discharge Port | 450mm | |

| Reaction Temperature of Kettle Body | -80~250ºC | |

| Ultrasonic Power | 2000W | |

| Ultrasonic Frequency | 20kHz | |

| Vacuum Degree | 0.098Mpa | |

| Rotating Speed of Stirring | 0-450rpm | |

| Diameter of Stirring Shaft | 12mm | |

| Stirring Power | 90W1/3 | |

| Power/Frequency(V/Hz) | 220V/50Hz | |

| Overall Dimension(mm*mm*mm) | 520*520*2000 | |

| Package Dimension(mm*mm*mm) | 1370*590*800 0.65 square meter | |

| Package Weight(KG) | 98 | |

| Function Configuration | Speed Regulation Mode | Electronic stepless speed regulation |

| Motor Configuration | Low speed booster motor, speed ratio is 3:1 | |

| Speed Display Mode | LCD digital display | |

| Temperature Display Mode | PT100 sensor digital display | |

| Sealing Method | Mechanical seal, ¢50 flange stirring port | |

| Condenser | Vertical high efficiency double reflux condenser pipe 100*670mm | |

| Reflux (Distillation) Device | Return elbow with discharge switch, 50# ball-milling mouth | |

| Dropping Device | 1L constant pressure funnel, 40# standard port | |

| Pressure Reducing Device | 34# standard port pressure reducing valve | |

| Ultrasonic Device | ¢80 flange coupling | |

| Ultrasonic Control | Touch screen LCD digital display | |

| Temperature Measuring Tube | 24# standard port | |

| Solid Feed | ¢80 flange mouth with PTFE cover | |

| Discharge Mode | Oblique type glass discharge valve, ¢80 flange mouth | |

| Vacuum Display Mode | Vacuum Gauge | |

| Stirring Connection Mode | Universal joint connection | |

| Stirring Rod | Anchor stainless steel rod, wrapped in PTFE | |

| Optional Configuration | Main Support | Tray type |

| Receiving Device | Receiving flask | |

| Explosion Proof | Explosion-proof frequency, explosion-proof motor, EX180W, 0-1400rpm | |

| Frame Part | Plastic spraying or PTFE spraying | |

| Insulated Device | Insulated cotton | |

| Sealing Part | Ceramic bearing, mechanical sealing | |

| Condenser | The horizontal condenser can lower the overall height. | |

| All laboratory instrument in our factory is independently researched and developed, and other laboratory instrument can be customized according to the actual requirements of customers. | ||

An ultrasonic double layer is an ideal equipment for lab-scale and pilot tests, biopharmaceutical, new drug research and development and new material synthesis. It is primarily used in small chemical industry, petroleum, metallurgy, coal, electronics, building materials, light industry and other fields, or the medium and small scale production.

Our Service

Our ServicePre-Sale Service

- Provide 24-hour technical consultation and reply;

- Provide professional quotation information;

- Provide detailed product performance specification;

- According to product's using condition, technicians will offer rationalization proposals to assist clients to select proper product types;

- Provide other corollary equipment according to client requirements.

In-Sale Service

- With supervision from the source of products, the qualified rate of raw materials entering the factory can reach 100%;

- Whole manufacturing process are in strict accordance with promised procedure requirements, product qualified rate can reach 100%;

- Provide product's inspection record of key junctures to customers;

- Provide production schedule photos to customers at regular intervals;

- Package and transport of products are in strict accordance with the export standard;

- Provide transportation schedule information to clients timely.

After-Sale Service

- Provide targeted installation video;

- Under the premise of correct installation, normal maintenance and using, we guarantee one-year warranty period;

- When warranty period has expired, our sold products enjoys lifetime guarantee repair, we only charge cost price for changing product's standard component and sealing component;

- During installation and adjustment period, our after-sale service staff will communicate with customers frequently to know product's running state in time. Assist customers to install and adjust products until customers are satisfied;

- If product has malfunction during operation period, we'll offer you satisfied answer in time. We'll reply you within 1 hour and provide solution or send staff to spot within 24 hours after receiving maintenance notification;

- Lifelong free technical support. Conduct satisfaction survey and inquiry equipment running condition to clients by telephone or e-mail semiannually from the first day of equipment running, put on records of acquired information;

- Provide assistance in solving problems such as equipment damage in the transport.