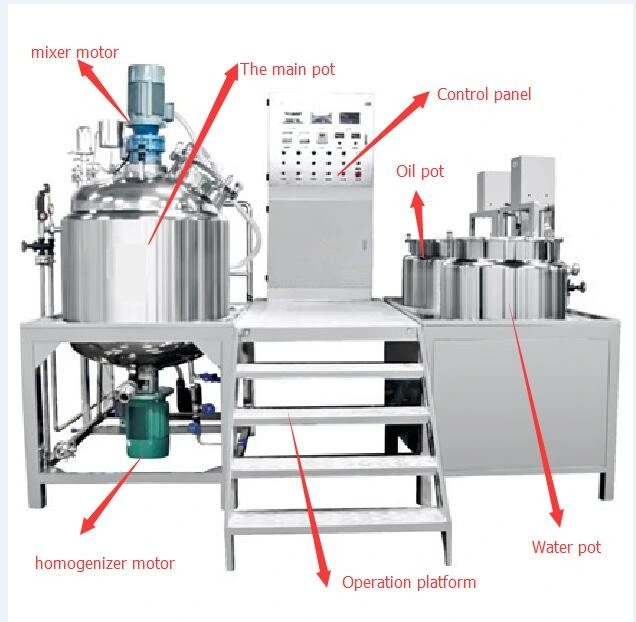

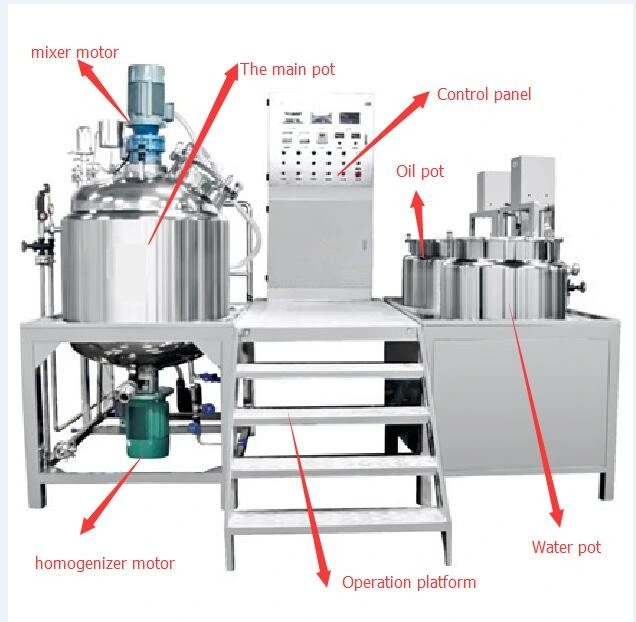

Main pot

Oil pot

water pot

Assemble mixed platform

Power consumption

Facility and electric

| No. | Method | Specification | Remarks |

| 1 | Stirring method | 1.one way scraping agitator blade ,power 7.5 KW,speed 0-63r/min | frequency control scrap wall material :polytetrafluoroethylene |

| 2.homogenizer power 11KW, speed 0-3000r/min | Frequency control | ||

| 2 | Sealing process | Machinery Seal | |

| 3 | Inlet material | Vacuum suction | |

| 4 | Discharge material | Pneumatic or direct ball valve | |

| 5 | Temperature shows | resistance thermometer(≤200ºC) | |

| 6 | Pressure and vaccum | Vacuum gage ,max-0.08Mpa | |

| 7 | Heating cooling method | Bottom electric heating, jacket water cooling, heating power: 18kw. | |

| 8 | Main technique | 1.working pressure of jacket 0.1Mpa | |

| 2.design volume 1050L | |||

| 3.working volume 800L-1000L | |||

| 9 | Material | 1.contact material all is 316L,Thickness 6mm | Inside polishing |

| 2.jacket SUS316L,thickness 4mm | Insulation temperature :aluminum fiber cotton | ||

| 3.out shell pot material 316L,thickness 4mm | Outside polishing | ||

| 10 | Polishing process | More than 300m on polishing | |

| 11 | Cover area | 3350mm*3250mm*2710mm | |

| 12 | Higher | 2710mm | |

| 13 | Others | The parts contact material all is imported 316l ss |

Oil pot

| No. | Method | Specification | remarks |

| 1 | Stirring method | Bottom dispersion,power 1.5KW,speed 960r/min | |

| 2 | Boil pot open | Half open | |

| 3 | Discharge method | By ball valve | |

| 4 | Temperature shows | resistance thermometer(≤200ºC) | |

| 5 | Main technique | 1.bottom electric heating,heating power :18kw working pressure<0.1Mpa | |

| 2. design volume 600L, working volume 500L | |||

| 6 | Material | 1.inside pot 316L | Inner polishing |

| 2.jacket material 304 | Insulation temperature :aluminum fiber cotton | ||

| 3.outside material 304 | Outside polishing | ||

| 7 | Polishing | More than 300m polishing result |

water pot

| No. | Method | Specification | Remarks |

| 1 | Stirring method | Bottom dispersion,power 1.5kw, speed 960r/min | |

| 2 | Boil pot open | Half open | |

| 3 | Discharge method | By ball valve | |

| 4 | Temperature shows | resistance thermometer(<200ºC) | |

| 5 | Main technique | 1.bottom electric heating,heating power :18kw working pressure<0.1Mpa | |

| 2. design volume 750L; working volume 600L | |||

| 6 | Material | 1.inside pot 316L, | Inner polishing |

| 2.jacket material 304 | Insulation temperature :aluminum fiber cotton | ||

| 3.outside materail 304 | Outside polishing | ||

| 7 | Polishing | More than 300m polishing result |

| No. | Name parts | Specification | Remarks |

| 1 | Stand hold and platform | ss stand hold ,decorative pattern ss sheet | |

| 2 | Emulsifying pot | Include inlet outlet ,manhole,thermometer ,material filter, spice bucket etc | |

| 3 | Pipe | Contact materail pipe all 316l ss | |

| 4 | Electric control cabinet | Whole ss make ,control main pot ,oil ,water pot | Push buttom by hand |

Power consumption

| Name | Specification | Remarks |

| 1000Lemusifying pot | 1.framed scraping wall paddle7.5KW | |

| 2.homogenizer11KW,bottom homogenizer, heating power :18kw | ||

| 500L oil pot | Pulwheel propeller,1.5KW,heating power :18kw | |

| 600L water pot | Pulwheel propeller ,1.5KW,heating power:18kw | |

| Vacuum pump | 2.85KW | |

| Voltage | 380V/50HZ 3Phase |

| No. | Name | Brand or orgin place | Remarks |

| 1 | Inverter | DELIXI | |

| 2 | Motor | SIEMENS | |

| 3 | Electic button | DELIXI | |

| 4 | Vacuum pump | ZIBO | |

| 5 | Main electric components | DELIXI |